Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

In New South Wales, SMEC is facing several design challenges head-on by leveraging Civil3D, Dynamo and Revit in innovative ways.

The Albion Park Rail Bypass project is one of the most complex infrastructure projects in New South Wales with a variety of environmental, design and project delivery challenges necessary to overcome. SMEC was able to meet and exceed time, cost and BIM requirements through the use of technology and by partnering with Autodesk to adopt new ways of managing and executing on the project. Through the use of Civil3D, Dynamo and Revit, SMEC achieved enormous success and set a new standard for BIM projects in New South Wales.

BIM compliant designs require a new approach to large-scale infrastructure projects

When engineering and development consultancy firm, SMEC, first took on the Albion Park Rail Bypass (APRB) project in New South Wales, also up for this year’s Consult Australia Award in the Technical Innovation category, they knew they had an exciting project in front of them. Soft soils, bridges crossing the highway, rail lines and a major rivulet all in addition to working adjacent to a live airport were only some of the challenges the design team faced. There was a large amount of work to be completed and many constraints to be dealt with whilst still achieving the deadlines.

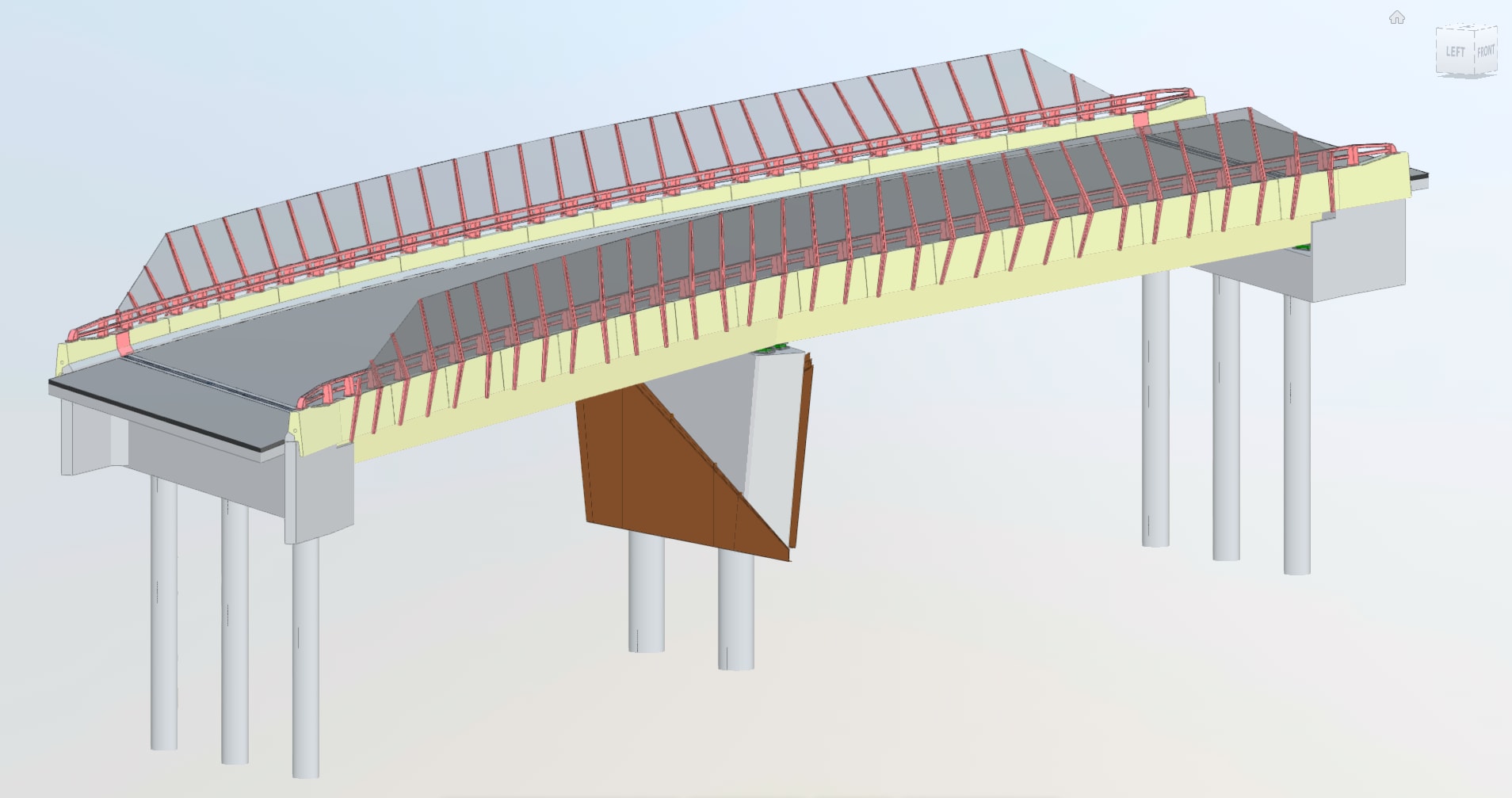

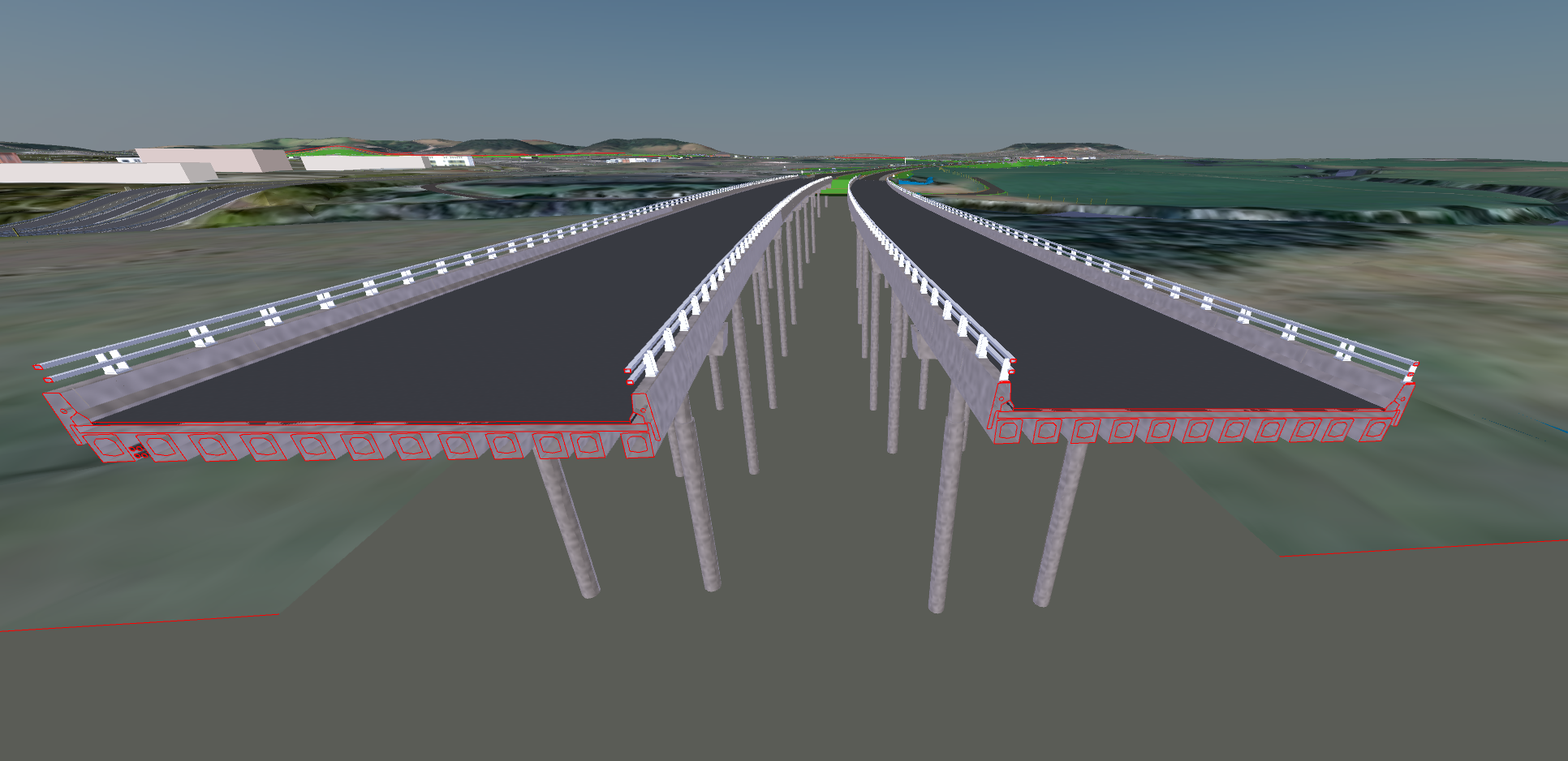

The APRB is a 9.8-kilometer extension of the existing M1 Princess Motorway between Yallah and Oak Flats. The project included 2,000,000m3 of earthworks and 14 bridges with multiple design iterations for each, and SMEC’s calculations for hours to be completed were very high and costly. The traditional process for developing these types of designs included the use of 2D drafting and string-based modeling between Civil 3D and Revit which just wasn’t going to cut it this time. The team also had to manually recreate the design in Revit–a process that’s incredibly inefficient and time-consuming.

SMEC’s team knew they needed to adopt new ways of working to ensure efficient delivery of the project on time and within budget. Furthermore, delivering a BIM compliant design for these bridges with all the design iterations necessary required an eight-person team from the outset. This is double the size SMEC would typically allocate to a project like this.

I think Albion was one of the first major motorway projects we did in full DE [Digital Engineering] where we had to supply everything, including bridges, utilities, drainage, roads, signage, and lighting. Everything you can think of had to be done, and on a scale that was a big challenge for us, but we did have a few team members who were able to get together and work with Autodesk on some ideas for how this could be done. The old way of doing it was simply too time-consuming and very slow.

—Mark Hynes, Manager of Technical Services Infrastructure, SMEC

Pioneering Digital Engineering to drive project delivery

“I think Albion was one of the first major motorway projects we did in full DE [Digital Engineering] where we had to supply everything, including bridges, utilities, drainage, roads, signage, and lighting,” says Mark Hynes, SMEC’s Manager of Technical Services Infrastructure. “Everything you can think of had to be done, and on a scale that was a big challenge for us, but we did have a few team members who were able to get together and work with Autodesk on some ideas for how this could be done. The old way of doing it was simply too time-consuming and very slow.”

Utilizing innovative technology through the use of Autodesk Revit, Dynamo, and Civil 3D, SMEC was able to successfully address bridge design challenges using automation and visual scripting, resulting in the reduction of bridge modelling time from 5-7 days to 3-5 days. With the help of Autodesk, the team underwent an in-depth health check on project setup and workflows in both Civil 3D and Dynamo in relation to the project. Autodesk's consulting services were critical to the design scheme’s overall success.

“We weren’t able to really model the alignments accurately with just Revit because it’s a building software,” says SMEC’s Senior Designer of Roads & Highways, Scott Warner. “It likes to just be square and flat, so we’ve had to use these Dynamo scripts to bring in the complicated geometry like curves and spirals. We really needed it to do the bridge decks.”

A substantial amount of on-the-job training took place in order to get everyone on board with the new technology, and the team had to learn things quickly. “It wasn’t just Dynamo that people needed to be trained in, but Civil 3D as well. There was training to do in every package,” says Hynes. “Everyone gets thrown in the deep end a little bit, but we had a good mix of skills on the team to be able to train the other people.”

Civil 3D proved very useful to the team with regard to workflows that weren’t working as they could have. “We coordinated with the development team about our challenges and the update they pushed out for Civil 3D reduced our synchronizing times down from one and a half hours to just a few minutes,” says Warner. “That solution came from the Albion Park project which, for me, was probably the biggest game-changer.”

The APRB project was a massive success for SMEC with Transport for NSW and the RMS working toward a policy requiring all major infrastructure projects utilize BIM and Digital Engineering. “Every project for the RMS now has some BIM requirements,” says Hynes. “And it has different levels of digital engineering. They’re adopting Uni Class 2015 as their standard and they’ve also got their own location, space, and asset data. It’s really evolved––the days of creating a few strings and tins as the core of the road design are gone. The focus is now solid based. We have several projects now following this methodology.”

SMEC has received a lot of positive feedback in response to the new workflows. RMS specifically has expressed a great deal of satisfaction with early-stage performance, particularly in relation to utilities and drainage. Once they recognized how powerful the information coming through was and were able to visualize the work SMEC was going to do, they were very happy.

“We’d often hear clients say things like, ‘projects haven’t changed––it’s still business as usual,’” says Warner. “We knew it wasn’t. We knew we had all these attributes and data which had to be attached to the model elements and it took quite some time for clients to realize the potential of the data we were pushing out. But once they did see it, they’d pick it to pieces and get a lot of value out of it.”

The Revit/Dynamo/Civil 3D offering that SMEC applied throughout the APRB project had never been implemented in the Australian market before, and the firm’s partnership with Autodesk was the catalyst to its deployment. At a fundamental level, these Dynamo-based workflows are having a profound impact on SMEC’s offerings that clients are really beginning to recognize. They also enable better collaboration among team members around the world. It’s ground-breaking technology that leads to more opportunities for SMEC to expand its global footprint even further, all while positioning the firm as a leader in sustainable and optimized construction methods.

Find out more about Autodesk's AEC Collection.